Vacuum Oven Moisture Determination

70 o c instead of 100 o c and so problems associated with degradation of heat labile substances can be reduced.

Vacuum oven moisture determination. The percent loss is then calculated. Drift determination to compensate moisture. Application of the vacuum oven to moisture determination in biological materials abstract. Browning index and colorimetry were measured to characterize the color and extent of browning.

Cheddar and low moisture part skim lmps mozzarella cheeses were prepared with 1 3 and 5 added lactose or galactose and subjected to either vacuum oven or microwave based moisture determination methods. This video is also available in english determination of moisture content by loss on drying method english https youtu be yp7sai2bbzq how to download not. The optimum conditions for the determination of the moisture content of biological materials using a vacuum oven have been investigated. Moisture oven found in.

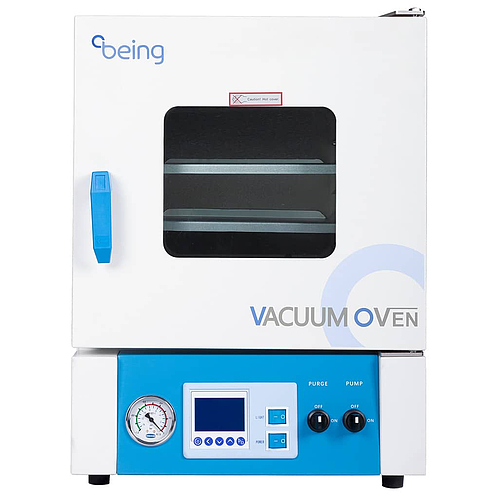

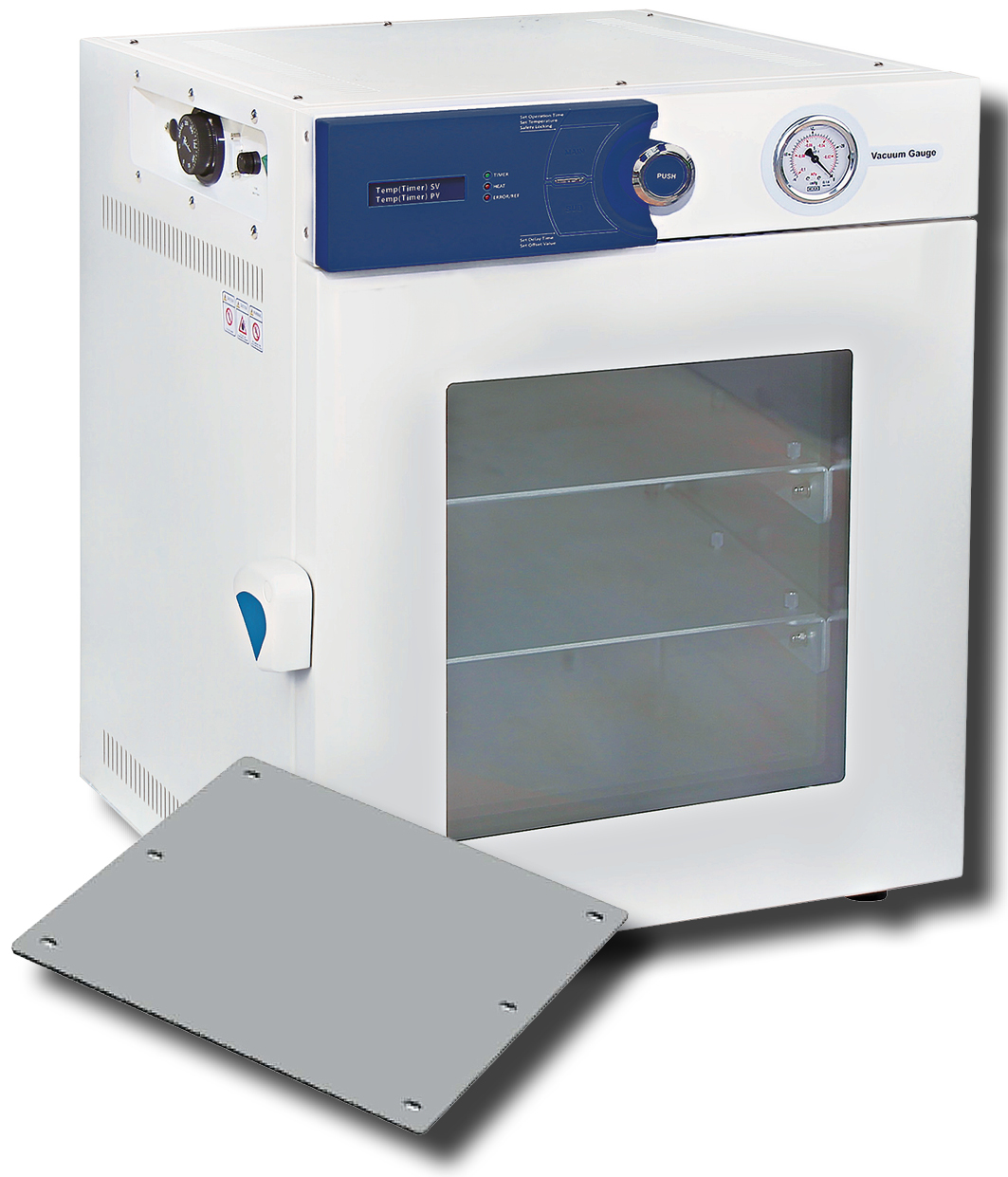

Four hours drying time was taken as a pre requisite to allow two determinations per day. Drying foods in a vacuum oven therefore has a number of advantages over conventional oven drying techniques. In our factory these ovens are made in both rectangular and cylindrical round shapes with temperature range up to 150 c 200 c optional. 10 10 sample is weighed transferred to the flask and placed in a vacuum oven where the sample is dried at 60 c with a pressure of 5 mm or less of mercury for three hours.

If the sample is heated at the same temperature drying can be carried out much quicker.