Vacuum Bag Oven Process

We re in the lab.

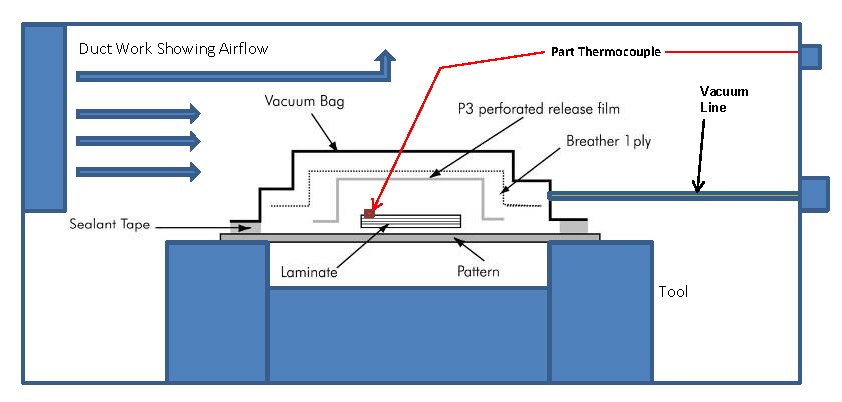

Vacuum bag oven process. Applying surface heat normally up to 392 f 200 c is required to successfully complete a vacuum bake out process. This video shows how we use the vacuum oven to evaporate off excess ethynol to increase the concentration during the thc extraction process. One common arrangement is for one or more vacuum source aka active connections to provide the vacuum to the part and for a static aka passive line to be connected to the other end of the part fig. The vacuum valves transducer pump and other components are located outside the oven and there are penetrations through the oven wall for the vacuum lines.

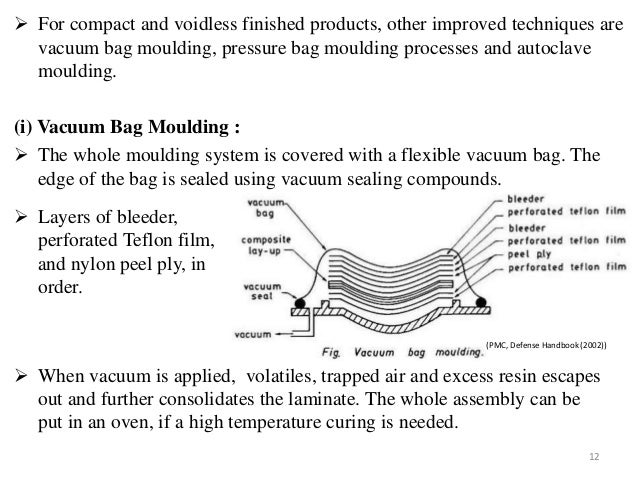

The vacuum bagging process is a manufacturing process for composites products which utilizes a flexible and transparent film in order to fully enclose and compacting the wet laminate by using atmospheric pressure. This type of process does not require large capital expenditures for tooling and processing equipment. The material is then covered with an impervious film the vacuum bag which is sealed around the edge of the part. Figure 14 23 illustrates the basic configuration of the vbri process which uses an open mould rather than the two piece closed mould of the rtm and vartm processes.

Tip 4 check your pump oil for color clarity and level before starting the process and regularly during use most especially during cold boiling under vacuum. This process can produce laminates with a uniform degree of consolidation while at the same time removing entrapped air thus reducing the finished void content. In this article you learn why you should switch over to the vacuum infusion process. The removal of impurities allows vacuum baked components to be used in ultra high vacuum or ultra high purity systems without fear of contamination.

This results in vbri having lower tooling costs which can be a large capital cost. We prefer a clear colorless pump oil so we can see if it is contaminated by looking at it through the oil level view window. By evacuating the air between the mould and the vacuum bag using a vacuum pump the part is consolidated under atmospheric pressure. The process is often performed in an oven to assist with the curing of the resin.

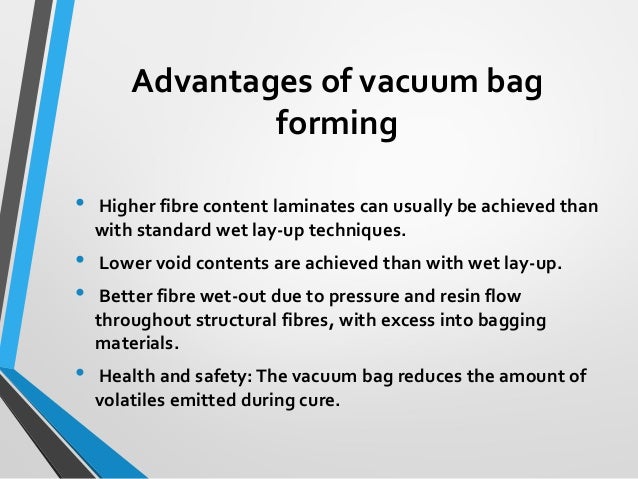

A vacuum bake out is a process used to remove such contaminants. Vacuum bag molding improves the mechanical properties of open mold laminates. Evaluation of double vacuum bag process for composite fabrication a non autoclave vacuum bag process using atmospheric pressure alone that eliminates the need for external pressure normally supplied by an autoclave or a press is an attractive method for composite fabrication.

.jpg)